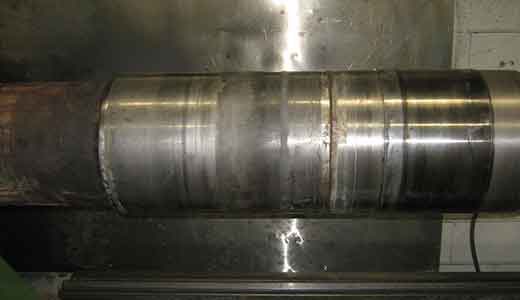

Spray Welding

Thermal Arc Spray Welding

When it comes to rebuilding, anti-wear, and anti-corrosion cold arc sprayed coatings, Nechako Steel & Machine utilizes the latest technology developed to improve running costs, coating deposition and ease of maintenance.

Spray welding provides a lot of benefits compared with conventional welding processes used for wear protection:

- Most substrate types can be coated (eg: both ferrous and non-ferrous materials, including — but not limited to — cast iron, stainless steel, and titanium

- No thermal distortion or metallurgical alteration of the substrate

- Low pre-heating requirements

- Low heat input during spraying

- No heat treatment after coating

- No dilution of the coating

- Fastest coating speeds

- Better control over deposit thickness reducing machining time and saving materials